Metallic ACP Sheet DHPE Coating

Product Details:

| Place of Origin: | China |

| Brand Name: | richly bound |

| Certification: | ISO 9001:2008;GB 8624-2012;GB/T 17748-2016 |

| Model Number: | A2 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 sqm |

|---|---|

| Price: | depends on your needs |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Delivery Time: | usually within 14 working days |

| Payment Terms: | T/T |

|

Detail Information |

|||

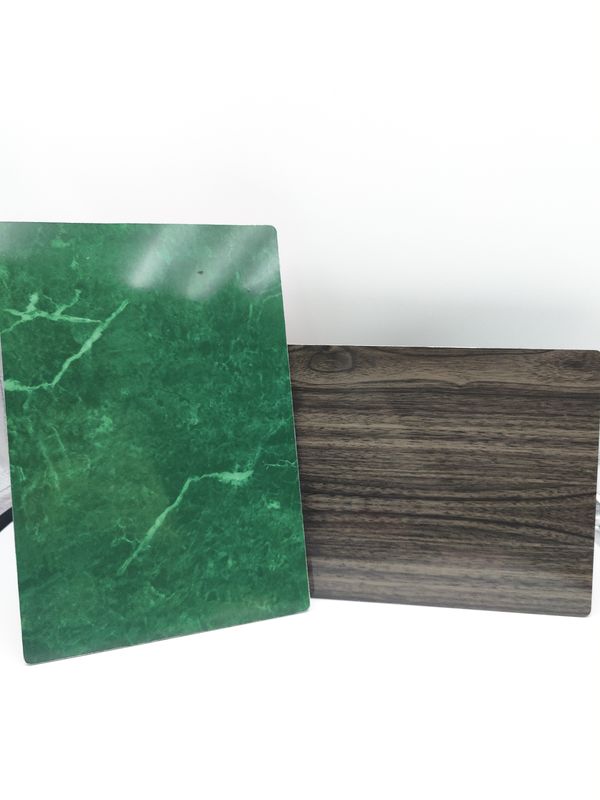

| Aluminum Layer Thickness: | 0.1mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm | Surface Color: | Regular Color,Solid Color,High Gloss,Wood Grain,Stone Grain,Mirror Finish,Brushed,Special Effects |

|---|---|---|---|

| Application Fields: | Exterior Wall, Balcony, Ceilings, Partitions, Doors, Column Casings, Equipment Panels, Interior Decoration, Interior Design, Furniture Surfaces, Curtain Walls, Billboards, Exhibitions, Signs, Signboard Doors, Coffee Shop Interior Design, Renovation Of Old | Surface Coating: | Polyester (PE),High-performance Polyester (DHPE),Fluorocarbon (PVDF),PVC Film,Anodized |

| Size: | 1220mm * 2440mm,Customizal | Sheet Thickness: | 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm |

| Highlight: | Metallic ACP Sheet DHPE Coating,Metallic ACP Sheet For Furniture,DHPE Coating Silver ACP Sheet |

||

Product Description

Metallic ACP Sheet / 2.0mm for Furniture Surfaces with DHPE Coating

Product Description:

The aluminum plastic panel is a composite material, incorporating the best traits of its metal and non-metal components. It combines the robustness of metal aluminum with the versatility of polyethylene plastic, by mitigating the weaknesses of its base materials.

The aluminum plastic panel offers a myriad of remarkable features, such as:

- High-end aesthetics

- Colorful appearance

- Resistance to weathering, corrosion, and impact

- Fire and moisture prevention

- Sound and heat insulation

- Earthquake resistance

In addition, the panel is characterized by its lightness in weight, effortless processing, and simplicity in transportation and mounting.

Features:

Boasting an exceptional strength-to-weight ratio, aluminum composite panels have a mass per unit area roughly 60% that of aluminum sheets, and only a third of steel ones.

Unlike aluminum sheets, aluminum composite panels have a significant 180° peel strength that keeps them in place for extended use.

Their coating remains stable and offers a durable performance even after prolonged outdoor exposure, with no flaking and a lifespan of over two decades.

The surface coating of aluminum composite panels has powerful adhesion and is resistant to corrosive effects of acids (10%H2S04), alkalis (10%NaOH), and saline fog, while the PVDF fluorocarbon resin coating is particularly robust.

It also meets Grade A national wind load endurance standards for outdoor decoration on high-rise buildings.

Added protection is sourced from the non-toxic polyethylene core layer, sandwiched between two non-flammable thin aluminum sheets, meeting the requirements of GB8624-2006 B1 grade fire resistance.

Technical Parameters:

Applications:

As a popular choice for exterior facing, architectural facades are used on a variety of structures, including skyscrapers, residential houses, corporate workspaces, and business towers.

Not just on the outside, architectural facades are also utilized to enhance the aesthetic appeal of the interior of residences, workspaces, and commercial locales, such as wall installations, ceiling concepts, and dividing panels.

Many businesses employ architectural facades in outdoor advertising, storefront displays, directional markers, digitally printed signs, and exhibition stages.

Within the transportation sector, architectural facades can be found in the construction of vehicle components for buses, trains, metro systems, aircraft, and seafaring vessels.

In residential settings, architectural facades are commonly used for home furnishing purposes, such as the fashioning of furniture, cupboards, kitchen counter surfaces, and other domestic fixtures.

Architectural facades can also be implemented in industrial operations, particularly for the manufacture of shell materials of machinery, shielding for tools, and sterile rooms.

Furthermore, structural facades are a common feature in shopfront designs, with retail outlets, booth structures, and indoor display modules all incorporating this popular material.

Product processing performance:

Our manufactured aluminum composite panels are readily tailored using both woodworking and metalworking instruments. Operations such as chopping, sectioning, milling, perforating, compressing, folding, and arching are possible. This ensures architectural decorative requirements are met with precision, especially designs like curves, opposing curves, minimal bend edges, and both inner and outer angles. Such adaptability is not often seen in other ornamental resources.

1.Segmenting: Tools span from hand-operated to electric and ring saws.

2.Ridge Milling: Post-processing with a mobile milling machine, one can shape it into diverse polyhedral figures.

3.Corner Deduction: After operations with a perforating device and corner reduction equipment, integration is achievable.

4.Binding: Combine using hot wind devices and plastic welding sticks.

5.Angle Molding: Following ridge milling, the desired angles can be formed.

6.Arching: Utilize 3-pivot or 3-barrel machines for this purpose.

7.Marking: Utilize screen print boards for markings.

8.Consolidating: Use mechanisms like rivets, spikes, and automated screws.

9.Puncturing: Perforations are feasible with a general puncher.

FAQ:

-

Q: What is the brand name of Metallic ACP Sheet?A: The brand name of Metallic ACP Sheet is Richly Bound.

-

Q: What is the model number of Metallic ACP Sheet?A: The model number of Metallic ACP Sheet is A2.

-

Q: Where is Metallic ACP Sheet made?A: Metallic ACP Sheet is made in China.

-

Q: What certifications does Metallic ACP Sheet have?A: Metallic ACP Sheet has ISO 9001:2008;GB 8624-2012;GB/T 17748-2016 certifications.

-

Q: What materials is Metallic ACP Sheet made of?A: Metallic ACP Sheet is made of aluminum composite panel.