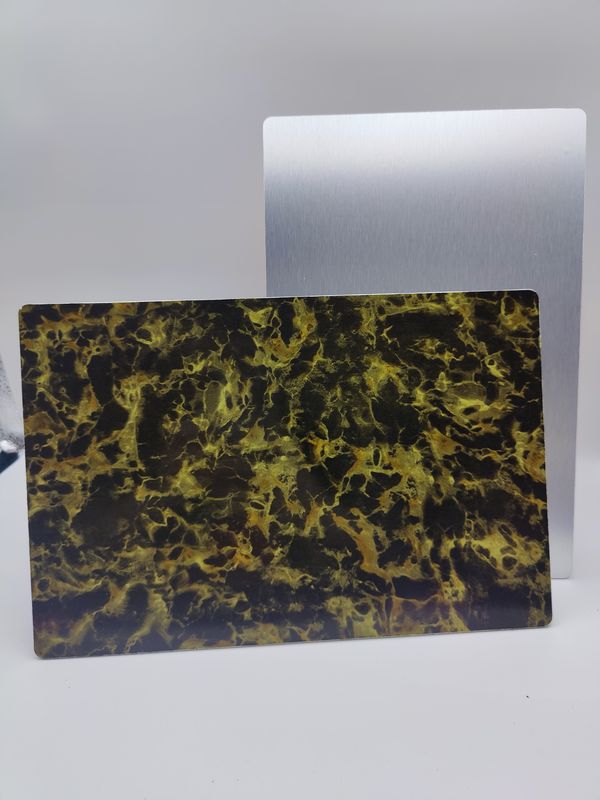

Anodized Mirror Gold ACP Sheet

Product Details:

| Place of Origin: | China |

| Brand Name: | richly bound |

| Certification: | ISO 9001:2008;GB 8624-2012;GB/T 17748-2016 |

| Model Number: | High-strength aluminum composite panel |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 sqm |

|---|---|

| Price: | depends on your needs |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Delivery Time: | usually within 14 working days |

| Payment Terms: | T/T |

|

Detail Information |

|||

| Surface Coating: | Polyester (PE),High-performance Polyester (DHPE),Fluorocarbon (PVDF),PVC Film,Anodized | Size: | 1220mm * 2440mm,Customizal |

|---|---|---|---|

| Sheet Thickness: | 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm | Surface Color: | Regular Color,Solid Color,High Gloss,Wood Grain,Stone Grain,Mirror Finish,Brushed,Special Effects |

| Aluminum Layer Thickness: | 0.1mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm | Application Fields: | Exterior Wall, Balcony, Ceilings, Partitions, Doors, Column Casings, Equipment Panels, Interior Decoration, Interior Design, Furniture Surfaces, Curtain Walls, Billboards, Exhibitions, Signs, Signboard Doors, Coffee Shop Interior Design, Renovation Of Old |

| Highlight: | Anodized Mirror Gold ACP Sheet,Mirror Gold ACP Sheet 1220mm,Anodized Composite Ceiling Cladding |

||

Product Description

Exhibition Use Mirror ACP Sheet, 3.0mm, Anodized, 1220mm * 2440mm

Product Description:

The Aluminum Plastic Composite as the Best of Both Worlds

The aluminum plastic composite is the ideal material, effortlessly combining two completely divergent materials: metal and non-metal. It conveniently bridges both metal and non-metal benefits and shortcomings while above all exhibiting the usual traits of these two materials, such as aluminum and polyethylene plastic. This combination results in superior properties compared to the use of either individual material.

These properties include: a luxurious, classy allure with vibrant colors, perfect for decorative purposes; an impressive resistance to weather, corrosion, impacts, fire, dampness, and sound; as well as the additional benefits of heat insulation and seismic resistance. As if this were not enough, the aluminum plastic composite has a lightweight construction which makes it easy to manipulate, transport and install.

Features:

Aluminum Composite Panels are praised for their exceptional strength-to-weight ratio. Compared to aluminum sheets of the same stiffness (E.j), its mass per unit surface is only 60% and 30% for steel sheets. Additionally, 180° peel strength is significantly robust, and the coating ensures no flaking and a good overall lifespan even after long-term outdoor exposure. The PVDF fluorocarbon resin coating is highly resistant to corrosion, anti-acids (10%H2S04) and alkalis (10%NaOH), as well as saline fog. In terms of wind load endurance, it meets the national grade A standard and is ideal for exterior decoration of high-rise buildings. Finally, the core layer is made of non-toxic polyethylene and shields two non-flammable aluminum sheets for fireproofing.

Technical Parameters:

Applications:

Aluminium composite panels are widely used for a variety of applications. Some of the areas where they are used include:

Building Exteriors: These panels are employed for cladding the exteriors of high rise buildings, bungalows, corporate offices, and commercial towers.

Building Interiors: They can also be used for interior decoration such as wall paneling, ceiling designs, and room partitions in homes, offices, and commercial spaces.

Signage: Aluminium composite panels are employed for outdoor signs, billboards, shopfront signage, direction signs, digital print signage, and display platforms.

Transportation: Furthermore, these panels are used in the manufacturing of body parts of transport vehicles such as buses, trains, metros, airplanes, and marine vehicles.

Furniture: They are also employed in furniture designs, wardrobes, kitchen cabinets and other interior fixtures.

Industrial Uses: Besides, aluminium composite panels are applied as casing materials for machinery in manufacturing units, as protective covering for equipment, and in cleanroom applications.

Retail Design: These panels can be also used for retail store setups, kiosk designs, and interior display units.

Hospitality Industry: They are employed for interior decorations, signage, and external cladding in hotels, resorts, and restaurants.

Healthcare Industry: ACPs are used due to their easy-to-clean and durable surface for cladding in hospitals, clinics, and health centers.

Education Sector: Aluminium composite panels are used in schools, colleges, and universities for signboards, furniture, and internal partitions.

Sports and Recreational Facilities: These panels are used for cladding, interior decorations, and signage in stadiums, gyms, and sports complexes.

Infrastructure: Lastly, these ACPs are used for cladding and signage in airports, railway stations, bus terminals, and ports.

Company Profile:

FAQ:

- Q1: What is Mirror ACP Sheet?

- A1: Mirror ACP Sheet is a high-strength aluminum composite panel produced by the brand of Richly Bound with certification of ISO 9001:2008;GB 8624-2012;GB/T 17748-2016, originated in China.

- Q2: What are the applications of Mirror ACP Sheet?

- A2: The applications of Mirror ACP Sheet include wall cladding, wall partition, ceiling panel, advertisement signboard, industrial material, etc.

- Q3: What are the features of Mirror ACP Sheet?

- A3: Mirror ACP Sheet is superior in flatness and rigidity, and is light in weight, easy in installation and excellent in fireproof performance.

- Q4: What is the production process of Mirror ACP Sheet?

- A4: The production process of Mirror ACP Sheet consists of surface treatment, lamination, cutting, packing, etc.

- Q5: What is the MOQ of Mirror ACP Sheet?

- A5: The minimum order quantity of Mirror ACP Sheet is 500 square meters.