Fire Rated ACP Sheets with More Than 10 Years Warranty for Office Interior

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | richly bound |

| Certification: | ISO 9001:2008;GB/T 17748-2016;GB 8624-2012 |

| Model Number: | A2 Fire Rated ACP Sheets |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 sqm |

|---|---|

| Price: | depends on your needs |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Delivery Time: | usually within 14 working days |

| Payment Terms: | T/T |

|

Detail Information |

|||

| Fire Rating: | A2,B1 | Application: | Exterior Wall, Balcony, Ceilings, Partitions, Doors, Column Casings, Equipment Panels, Interior Decoration, Interior Design, Furniture Surfaces, Curtain Walls, Billboards, Exhibitions, Signs, Signboard Doors, Coffee Shop Interior Design, Renovation Of Old |

|---|---|---|---|

| Material: | Aluminium Composite Panel | Aluminum Layer Thickness: | 0.1mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm |

| Core Material: | Non-combustible Plactic Core | Sheet Thickness: | 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm |

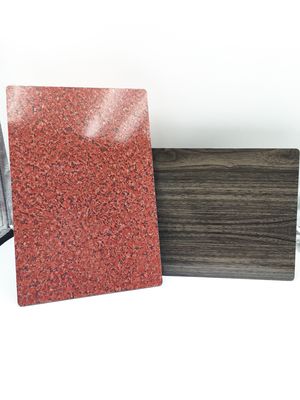

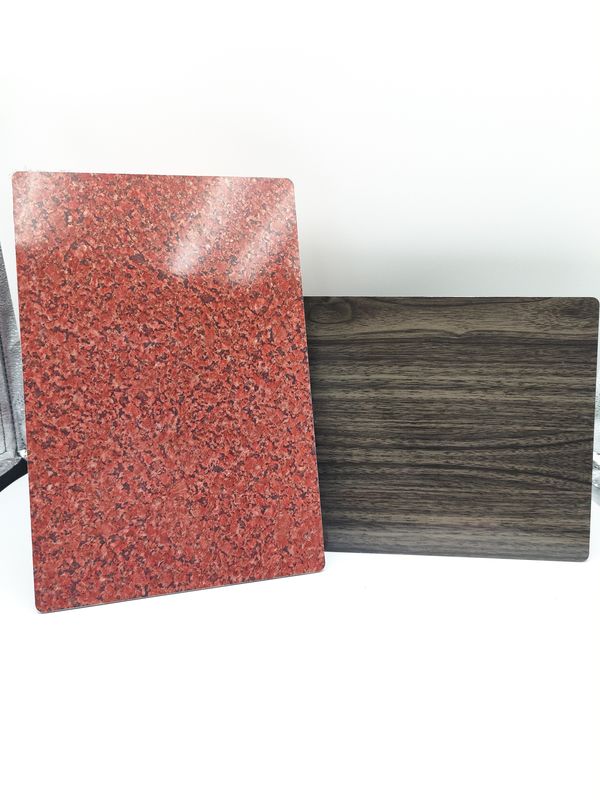

| Color: | Regular Color,Solid Color,High Gloss,Wood Grain,Stone Grain,Mirror Finish,Brushed,Special Effects | Length: | 2440mm |

| Highlight: | Fire Rated ACP Sheets |

||

Product Description

Product Description:

Aluminum plastic panel is a kind of flat panel comprised of a non-aluminum core stuck between two aluminum sheets. The coating of these panels involves PVDF or PE, which helps them obtain a wide range of colors and finishes.

Apart from architecture, aluminum plastic panels also find its application for advertising, shop facades, and interior decoration. This is because of its advantages, like longevity, light weight, formability, and energy efficiency. What makes them all the more desirable is their feature of being recyclable, which pertains to the increasing demand for sustainable materials in this modern world.

Features:

Aluminum-plastic panels have many advantages, making them a popular choice in the construction and decoration industry.

Lightweight Material: Aluminum-plastic panels are lightweight, making them easy to install and transport, thus reducing construction costs. Despite its lightweight, its strength and durability are not compromised.

Strong Weather Resistance: Aluminum-plastic panels have good weather resistance, which enables them to withstand harsh weather conditions such as strong sunlight, strong wind and rain, humidity, and temperature changes. This makes it suitable for outdoor construction and decoration.

Diverse Colors and Designs: Aluminum-plastic panels can offer a variety of colors and designs to meet individualised aesthetic needs. Its surface can be treated with various methods, such as spraying, coating, and printing to create eye-catching visuals.

Easy to Maintain and Clean: The surface of the aluminum-plastic panel is smooth and not easy to accumulate dust and dirt. It can be easily cleaned with a detergent and cloth. This material does not require special maintenance and can maintain its original appearance and performance for a long time.

Environmental Friendly: Aluminum-plastic panels are an eco-friendly material that does not release harmful substances. In addition, it is recyclable, which is beneficial to the environment.

Good Sound Insulation Performance: Aluminum-plastic panels have good sound insulation performance, which can prevent the spread of sound. This makes it suitable for places where sound insulation is needed, such as offices, hospitals, and schools.

Fire Resistance: Aluminum-plastic panels have good fire resistance. In the event of a fire, it can prevent the spread of flames and protect the structural safety of buildings.

Technical Parameters:

Applications:

Building exteriors are widely used for various applications. They are suitable for cladding high rise buildings, bungalows, corporate offices, and commercial towers. Moreover, their use is not limited to buildings, they can also be applied to transportation and infrastructure.

Building interiors are utilized for multiple purposes including wall paneling, ceiling designs, room partitions, and more. Utilized in homes, offices, and commercial spaces, they lend charm to otherwise boring interiors.

Exteriors and interiors are not the only uses of building materials. They are also used in the creation of billboards, shopfront signage, direction signs, digital print signage, and display platforms. This makes them a great choice for advertising.

Building materials are not just restricted to buildings, they are also useful in the manufacturing of body parts of buses, trains, metros, airplanes, and marine vehicles. This allows for greater flexibility in design and a more durable finish.

Building materials can also be applied to furniture. They are used in the creation of furniture designs, wardrobes, kitchen cabinet surfaces, and other interior fixtures. This allows for unique designs to be created.

Building materials can also be applied in industrial settings. Their uses include casing materials for machinery, protective covering for equipment, and cleanroom applications. Their versatility makes them the ideal choice for many industrial uses.

Building materials are also used in the creation of retail store setups, kiosk designs, and interior display units. This allows for a more pleasing and inviting atmosphere for customers.

They are also a great choice for the hospitality sector. They can be used for interior decorations, signage, and external cladding in hotels, resorts, and restaurants. This helps to give the place a unique and inviting atmosphere.

The healthcare sector also utilizes building materials. They are used for cladding in hospitals, clinics, and health centers due to their easy-to-clean and durable surface. This ensures the safety and hygiene of the patients.

Building materials can also be found in educational institutions. They are used in schools, colleges, and universities for signboards, furniture, and internal partitions. This allows for greater flexibility in design and a more aesthetically pleasing look.

The sports and recreation sector utilizes building materials as well. They are used in stadiums, gyms, and sports complexes for cladding, internal decorations, and signage. This helps to give these places a favorable atmosphere for athletes and their fans.

Building materials are also handy for infrastructure use. They are used for cladding and signage in airports, railway stations, bus terminals, and ports. This ensures better visibility and a more pleasing look.

Customization:

Fire Rated ACP Sheets is made of high-grade aluminum composite panel (ACP) aluminium with an aluminum layer thickness of 0.1mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm, sheet thickness of 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm and a width of 1220mm. It is designed for ACP cladding and provides excellent fire rated performance. It is perfect for any commercial and industrial applications and has a warranty of more than 10 years.

Our Company:

FAQ:

Q1: What is Fire Rated ACP Sheets?

A1: Fire Rated ACP Sheets are a type of fire-resistant aluminum composite panels that have been specially designed to be used in buildings and other structures where fire safety is a priority.

Q2: What are the benefits of using Fire Rated ACP Sheets?

A2: Fire Rated ACP Sheets offer superior fire-resistance and durability, as well as enhanced thermal insulation and sound insulation. They also have excellent weatherproofing and corrosion resistance.

Q3: What are the available sizes of Fire Rated ACP Sheets?

A3: Fire Rated ACP Sheets are available in a wide range of thicknesses, widths, and lengths, allowing for customization to suit any project.

Q4: What are the fire rating of Fire Rated ACP Sheets?

A4: Fire Rated ACP Sheets are rated up to a fire resistance of 4 hours.

Q5: How easy is Fire Rated ACP Sheets to install?

A5: Fire Rated ACP Sheets are easy to install, requiring only basic tools and skills. They can be cut, drilled, and shaped to fit any project.