DHPE Coating Exterior ACP Sheet Anodized Coating Aluminium Plastic Board

Product Details:

| Place of Origin: | China |

| Brand Name: | richly bound |

| Certification: | ISO 9001:2008;GB 8624-2012;GB/T 17748-2016 |

| Model Number: | High-strength aluminum composite panel |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 sqm |

|---|---|

| Price: | depends on your needs |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Delivery Time: | usually within 14 working days |

| Payment Terms: | T/T |

|

Detail Information |

|||

| Sheet Thickness: | 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm | Width: | 1220mm |

|---|---|---|---|

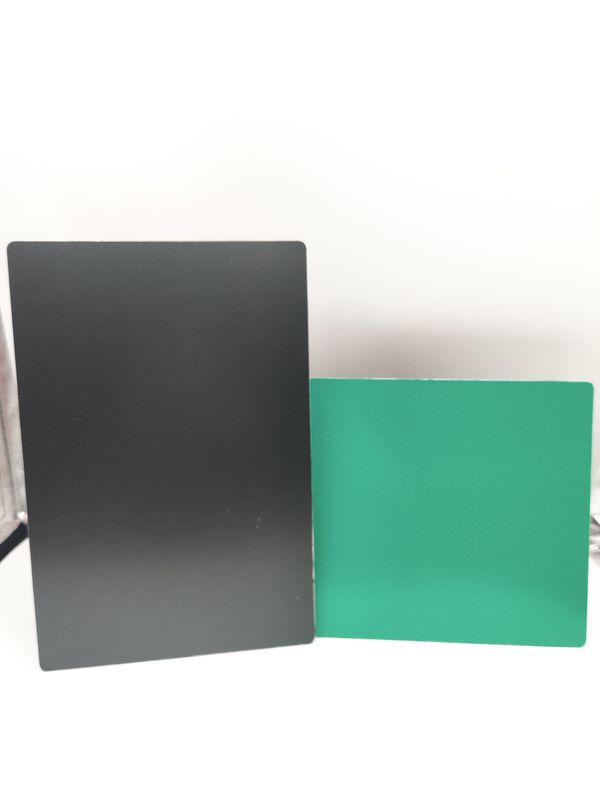

| Color: | Regular Color,Solid Color,High Gloss,Wood Grain,Stone Grain,Mirror Finish,Brushed,Special Effects | Material: | Aluminum Composite Panel |

| Application: | Exterior Wall, Balcony, Furniture Surfaces, Curtain Walls, Billboards, Exhibitions, Signs, Signboard Doors, Renovation Of Old Buildings, Purification And Dust Prevention Projects, House Design | Aluminum Layer Thickness: | 0.1mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm |

| Length: | 2440mm | Surface Coating: | Polyester (PE),High-performance Polyester (DHPE),Fluorocarbon (PVDF),PVC Film,Anodized |

| Highlight: | DHPE Coating Exterior ACP Sheet,Anodized Coating Exterior ACP Sheet,DHPE Coating Aluminium Plastic Board |

||

Product Description

Exterior ACP Sheet with 5.0mm Thickness, Wood Grain, Anodized Coating, for Balcony

Product Description:

In essence, aluminum plastic panel is a type of sandwich panel: it is composed of two aluminum sheets which enclose a non-aluminum core material, usually a polyethylene (PE) or fire-resistant (FR) base. This multi-layered material carries numerous attributes that make it an ideal choice in various industries for different aims and projects.

Aluminum plastic panel's usability is mainly due to its versatility: it can be cut, routed and formed into different shapes with little effort, ideal for those who are aiming for more design-oriented outcomes. Additionally, it has a superior durability, lightness, and ease of fabrication, which make it an excellent selection for applications such as construction, signage, and transportation.

Features:

Aluminum-plastic panels are a top choice in the building and decorating industry, both for their ultra-lightweight construction, making them easy to install and transport, and for their sturdiness and long-lasting durability.

Their superior weatherproofing capabilities make them an excellent option for outdoor buildign and decorating projects, as they can resist intense sunlight, wind, rain, and temperature variations.

The availability of a wide range of colors and styles to choose from allows for many aesthetic options. The surface of the material can be sprayed, coated, and printed for distinctive visual aesthetics.

The aluminum-plastic panel is also a low-maintenance, easy-to-clean material, as cleaning is as simple as wiping it down with a cloth and detergent. It requires no special upkeep and can maintain its original look and performance for a long time.

The material is highly environmentally friendly, as it does not release any harmful substances. Furthermore, it is recyclable, making it beneficial to environmental preservation.

Aluminum-plastic panels are also great for soundproofing, thus making them beneficial for offices, hospitals, and schools. Moreover, they are fire-resistant and can prevent the spread of flames, protecting the structural integrity of buildings.

Technical Parameters:

Applications:

Building Encasements are implemented for coating the exteriors of high-rise buildings, individual residences, business premises, andtrade structures. This application also covers decorative interiors, which are found in the inner decoration of homes, businesses, and corporate spaces. These may include decorative wall treatments, innovative ceiling concepts, and room partitions.

Signboards are used for large-scale advertisements, store-front signs, direction markers, digital billboards, and display podiums. In addition, transportation parts are manufactured using this application, such as components for buses, trains, metro services, aircraft, and seafaring vessels.

Even domestic furnishings are made with this material, including furniture designs, storage solutions, kitchen counter fronts, and other in-house fittings. Industrial applications are also incorporated in this process, utilizing the material as protective shells for machinery, coverings forequipment, and procedures for cleanroom environments.

Lastly, retail interiors are structured with the help of this material. This includes commercial outlets, kiosks, and in-store display units.

Product processing performance:

The versatility of the aluminium composite panels that our company produces is exemplary, as they can be transformed and processed using typical woodworking and metalworking tools. Actions like cutting, sawing, milling, punching, pressing, folding, and bending can be flawlessly performed, ensuring the exact completion of an array of forms required by architectural decoration design. Especially for shapes such as arcs, counter-arcs, small-radius corners, and internal and external corners, the level of adaptability surpasses other decoration materials.

1. Cutting: Cutting tool, electric saw, hand saw, ring saw, etc.

2. Slot Milling: After processing with an electric and portable slot milling machine, the product can be manually bent into various kinds of polyhedrons.

3. Corner Removing: After processing with a puncher and corner removing machine, it can be combined in a trunk.

4. Welding: The product can be welded with plastic welding rods and hot wind welders.

5. Corner Bending: After processing with a slot milling machine, the product can be bent into various corners.

6. Bending: The product can be bent using 3-point or 3-rolling machines.

7. Printing: The product can be printed with screen printing plates.

8. Assembling: Rivet, nail, self-tapping screw, etc.

9. Punching: The product can be punched with an open puncher.

FAQ:

- Q1: What is Exterior ACP Sheet?

- A1: Exterior ACP Sheet is a kind of high-strength aluminum composite panel produced by Richly Bound. It has been certified with ISO 9001:2008;GB 8624-2012;GB/T 17748-2016, and is made in China.

- Q2: What are the advantages of Exterior ACP Sheet?

- A2: Exterior ACP Sheet has many advantages such as strong strength, good flatness, good weather resistance, and long service life.

- Q3: What is the thickness of Exterior ACP Sheet?

- A3: Exterior ACP Sheet has a thickness of 3mm-6mm.

- Q4: What colors does Exterior ACP Sheet come in?

- A4: Exterior ACP Sheet is available in a variety of colors to suit your needs.

- Q5: How long is the warranty for Exterior ACP Sheet?

- A5: Exterior ACP Sheet has a 3-5 year warranty.