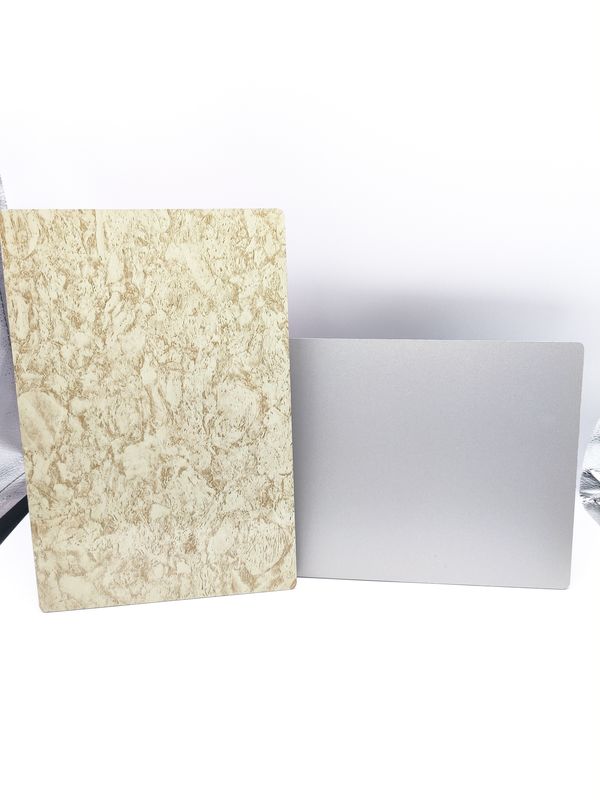

Anodised Aluminium Mirror ACP Sheet Plate 2mm Thickness With PVC Film

Product Details:

| Place of Origin: | China |

| Brand Name: | richly bound |

| Certification: | ISO 9001:2008;GB 8624-2012;GB/T 17748-2016 |

| Model Number: | High-strength aluminum composite panel |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 sqm |

|---|---|

| Price: | depends on your needs |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Delivery Time: | usually within 14 working days |

| Payment Terms: | T/T |

|

Detail Information |

|||

| Aluminum Layer Thickness: | 0.1mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm | Size: | 1220mm * 2440mm,Customizal |

|---|---|---|---|

| Surface Coating: | Polyester (PE),High-performance Polyester (DHPE),Fluorocarbon (PVDF),PVC Film,Anodized | Application Fields: | Exterior Wall, Balcony, Ceilings, Partitions, Doors, Column Casings, Equipment Panels, Interior Decoration, Interior Design, Furniture Surfaces, Curtain Walls, Billboards, Exhibitions, Signs, Signboard Doors, Coffee Shop Interior Design, Renovation Of Old |

| Sheet Thickness: | 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm | Surface Color: | Regular Color,Solid Color,High Gloss,Wood Grain,Stone Grain,Mirror Finish,Brushed,Special Effects |

| Highlight: | Mirror ACP Sheet 2mm,Mirror ACP Sheet With PVC Film,Anodised Aluminium Plate 2mm |

||

Product Description

2.0mm Mirror ACP Sheet with PVC film - Ideal for Equipment Panels

Product Description:

The aluminum plastic board is composed of two different materials - metal and non-metal. Combining their respective properties, the board has transcended the limitations of those two materials. This kind of board has plenty of advantages, such as luxuriousness, various colors, weather protection, anti-corrosion and anti-collision, fire and moisture proof, noise and heat insulation, and earthquake resistance. Furthermore, it has the features of lightness, easy to shape and simple to install and move.

Features:

The aluminum composite panels have a unique light weight. They have great strength-to-weight ratio. The aluminum composite panels are 60% the weight of aluminum panels and only 30% the weight of steel panels. These panels will also offer great adhesive strength with a 180 degree peeling strength. Due to their high adhesive strength, there will not be any spontaneous peeling between the aluminum sheet and the plastic core material, even when they have been in use for a long time.

When outdoor, these panels will not change their color or gloss for a long time with the coating remaining intact. The typical lifespan of these panels is over twenty years, which makes them great for outdoor usage. These panels also have anti-corrosive properties, as the surface coating maintains strong adhesions, and can withstand the corrosion of acid (10%H2S04), alkali (10%NaOH), and salt mist.

Wind load resistance for these panels is high A class. This means that they can resist the demand of wind load in high-rise building exterior decoration. The middle layer of these panels is composed of non-toxic polyethylene, and both the sides are encased by non-combustible thin aluminum sheets. This makes them fire resistant.

Technical Parameters:

Applications:

External Building Surfaces: Applied for exterior coverings of towering constructions, detached homes, corporate premises, and trade towers.

Indoor Embellishments: Utilized for interior design in residential, work, and commercial spaces, covering wall panelling, unique ceiling ideas, and room separators.

Directional and Marketing Signs: Incorporated for large outdoor advertisements, shop banners, navigational signs, digital print displays, and exhibition podiums.

Vehicle Manufacturing: Used in the fabrication of components for buses, trains, subways, aircraft, and marine vehicles.

Domestic Fixtures: Applied in the formulation of furniture patterns, storage units, kitchen top surfaces, and other indoor fittings.

Manufacturing Sector: Employed in industrial operations as enclosure materials for machines, safety covers for devices, and applications in sterile environments.

Store Designing: Implemented for retail store compositions, booth layouts, and inside display structures.

Our Company:

FAQ:

Q1: What is Richly Bound Mirror ACP Sheet?

A1: Richly Bound Mirror ACP Sheet is a high-strength aluminum composite panel made in China and certified to ISO 9001:2008;GB 8624-2012;GB/T 17748-2016 standards.

Q2: What are the benefits of Richly Bound Mirror ACP Sheet?

A2: Richly Bound Mirror ACP Sheet is lightweight, durable, and easy to install. It is resistant to UV radiation, corrosion, and other outdoor elements, making it ideal for outdoor applications.

Q3: What sizes are available for Richly Bound Mirror ACP Sheet?

A3: Richly Bound Mirror ACP Sheet is available in various sizes, from 1220x2440mm to 1550x5800mm.

Q4: What colors does Richly Bound Mirror ACP Sheet come in?

A4: Richly Bound Mirror ACP Sheet comes in a variety of colors, including metallic silver, bronze, and gold.

Q5: How do I install Richly Bound Mirror ACP Sheet?

A5: Richly Bound Mirror ACP Sheet can be easily installed with standard mechanical fasteners and adhesives. Please refer to the installation instructions for detailed instructions.