Fire Rated ACP Sheets Customizable Size With 0.15mm Alloy And Brushed Effect

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | richly bound |

| Certification: | ISO 9001:2008;GB/T 17748-2016;GB 8624-2012 |

| Model Number: | FR ACP Sheets |

Payment & Shipping Terms:

| Minimum Order Quantity: | 500 sqm |

|---|---|

| Price: | depends on your needs |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Delivery Time: | usually within 14 working days |

| Payment Terms: | T/T |

|

Detail Information |

|||

| Sheet Thickness: | 3.0-6.0mm | Aluminum Layer Thickness: | 0.12-0.5mm |

|---|---|---|---|

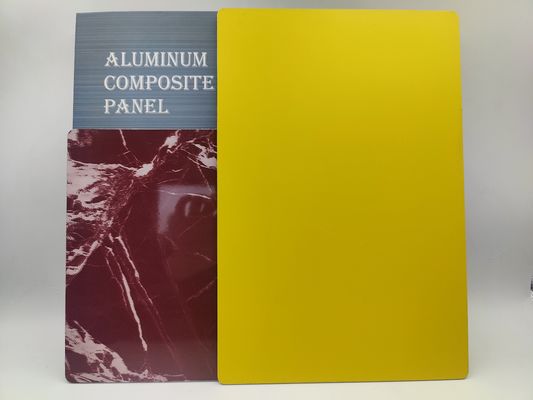

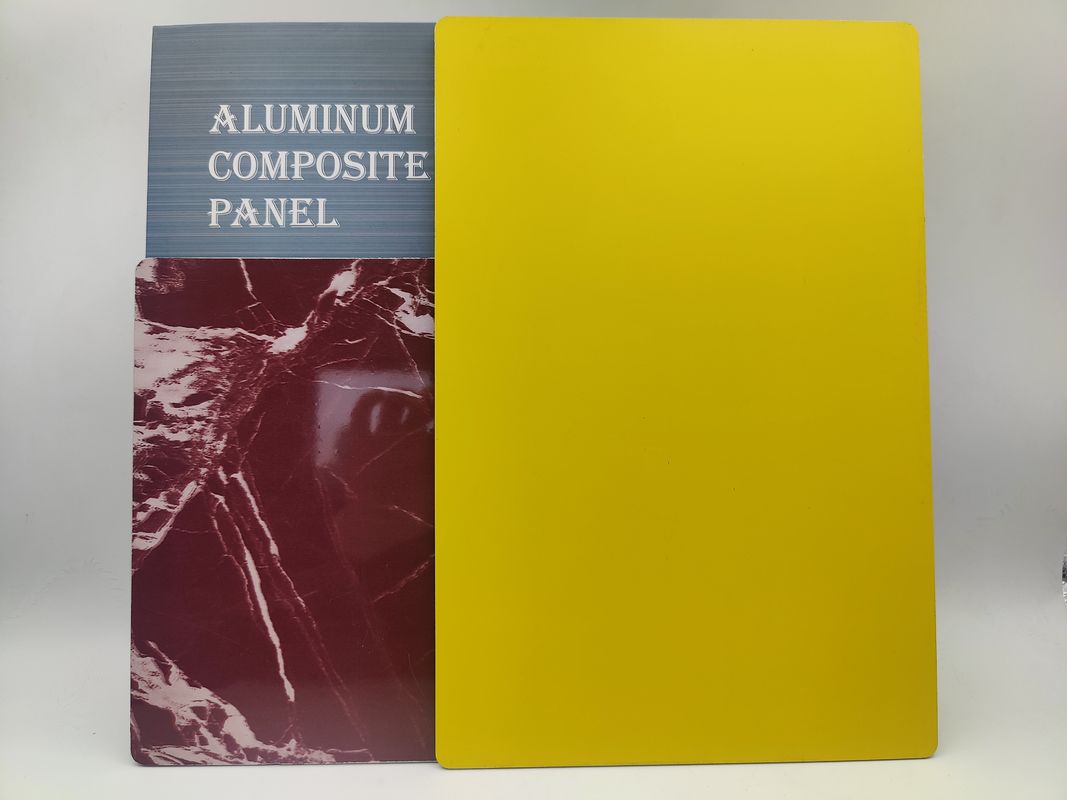

| Surface Color: | Solid Color,High Gloss,Wood Grain,Stone Grain,Mirror Finish,Brushed,Special Effects | Application Fields: | Exterior Or Interior Wall,balcony,ceilings,partitions,doors,column Casings,equipment Panels,interior Decoration,interior Design,furniture Surfaces,Curtain Walls,billboards,exhibitions,signs,signboard Doors,coffee Shop Interior Design |

| Surface Coating: | Polyester (PE),High-performance Polyester (HDPE),Fluorocarbon (PVDF),PVC Film,Anodized | Size: | 1220mm * 2440mm,4ft * 8ft |

| Highlight: | Brush ACP Sheet,Alloy ACP Sheet,Customizable Size Fire Rated ACP Sheets |

||

Product Description

Fire Rated ACP Sheets, Customizable Size with 0.15mm Alloy and Brushed Effect

Product Overview

The Fire Rated ACP Sheets with a 0.15mm aluminum alloy skin and a brushed surface finish are a refined and dependable cladding material designed for both functional and decorative interior applications. With their customizable dimensions, these aluminum composite panels offer flexibility for diverse project scales, while their fire-retardant properties meet essential safety requirements in public and commercial buildings.

Designed for architects, contractors, and furniture manufacturers seeking a sleek metallic aesthetic with added fire protection, these panels feature a realistic brushed effect on the surface—simulating stainless steel or anodized metal—without the weight, cost, or fabrication limitations of solid metal sheets.

Structure and Composition

Each panel is constructed using a mineral-filled fire-resistant core, laminated between two thin aluminum layers. The front aluminum skin, measuring 0.15mm, provides the necessary durability and flatness for interior wall systems, cabinet surfaces, and decorative enclosures. The brushed finish is achieved through a controlled texturing process that delivers a consistent grain, subtle sheen, and resistance to visible wear such as fingerprints or scratches.

Despite the thin alloy layer, the panel maintains excellent mechanical strength and flexibility due to its composite sandwich structure. It is easy to fabricate, cut, rout, and bend—making it suitable for precision installation in complex interior design systems or modular assemblies.

Fire Safety Assurance

These panels are manufactured to comply with fire safety regulations for interior materials. Based on test results provided by China Testing & Certification International Group Co., Ltd. (CTC) under report number WT2022B01B01694E, the panels are certified to meet A2-s1, d0, t0 classification as per GB 8624-2012:

-

A2: Non-combustible core structure

-

s1: Low smoke emission

-

d0: No flaming droplets during combustion

-

t0: Short burning time, no sustained ignition

This makes the product ideal for use in high-traffic areas such as office buildings, schools, transport terminals, hospitals, and retail environments where fire-rated materials are mandatory.

Technical Specifications

-

Panel Thickness: Common options include 3mm, 4mm, 5mm, and 6mm

-

Aluminum Skin (Front): 0.15mm alloy

-

Core Material: Non-toxic, halogen-free, fire-retardant mineral composite

-

Surface Finish: Brushed (silver, gold, bronze, or custom tones available)

-

Standard Size: 1220mm x 2440mm; custom dimensions available upon request

-

Surface Hardness: 2H

-

Coating Type: Polyester or anodized-type brushed finish

-

Weight: Approx. 4.5–5.5 kg/m² (varies by thickness)

Features and Advantages

-

Brushed Finish Aesthetic: Provides a modern, professional metallic texture ideal for indoor environments

-

Fire-Rated Safety Core: Offers essential flame-retardant properties for public-use building compliance

-

Custom Sizing Available: Allows adaptation to bespoke architectural and furniture requirements

-

Fabrication-Friendly: Compatible with CNC routing, bending, grooving, riveting, and adhesive installation

-

Lightweight Structure: Reduces labor and structural support requirements compared to solid aluminum

-

Scratch-Resistant Surface: Suitable for high-contact installations with sustained visual performance

Recommended Applications

-

Decorative wall cladding in offices, retail stores, and cultural venues

-

Cabinet panels, drawer fronts, and modular furniture systems

-

Column wraps and ceiling trims in public lobbies and corridors

-

Signboard backings and display surfaces

-

Interior partitions and paneling systems in educational or healthcare facilities

-

Elevator lobby detailing or stairwell wall surfacing

Conclusion

The Fire Rated ACP Sheets with a 0.15mm aluminum alloy and brushed effect combine safety, beauty, and adaptability in one cost-effective material. Suitable for modern architectural interiors and custom furniture, these panels are a smart choice for professionals who need performance, precision, and visual sophistication—without compromising on safety.

About the Manufacturer

About the Manufacturer

Foshan Nanhai Huashi Decoration Material Ltd., under the brand name Richly Bound, has specialized in the production of high-quality aluminum composite panels since 1999. We are committed to providing fire-rated ACP solutions for a wide range of architectural and signage applications. Our products are manufactured using advanced equipment, strict quality control systems, and offer global export support.

![]()