Brushed Aluminum Plastic Composite Panel , 4mm Panel 2440mm Length

Product Details:

| Place of Origin: | China |

| Brand Name: | richly bound |

| Certification: | ISO 9001:2008;GB 8624-2012;GB/T 17748-2016 |

| Model Number: | High-strength aluminum composite panel |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 sqm |

|---|---|

| Price: | depends on your needs |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Delivery Time: | usually within 14 working days |

| Payment Terms: | T/T |

|

Detail Information |

|||

| Sheet Thickness: | 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm | Application: | Exterior Wall, Balcony, Ceilings, Partitions, Doors, Column Casings, Equipment Panels, Interior Decoration, Interior Design, Furniture Surfaces, Curtain Walls, Billboards, Exhibitions, Signs, Signboard Doors, Coffee Shop Interior Design, Renovation Of Old |

|---|---|---|---|

| Size: | 1220*2440mm | Surface Coating: | Polyester (PE),High-performance Polyester (DHPE),Fluorocarbon (PVDF),PVC Film,Anodized |

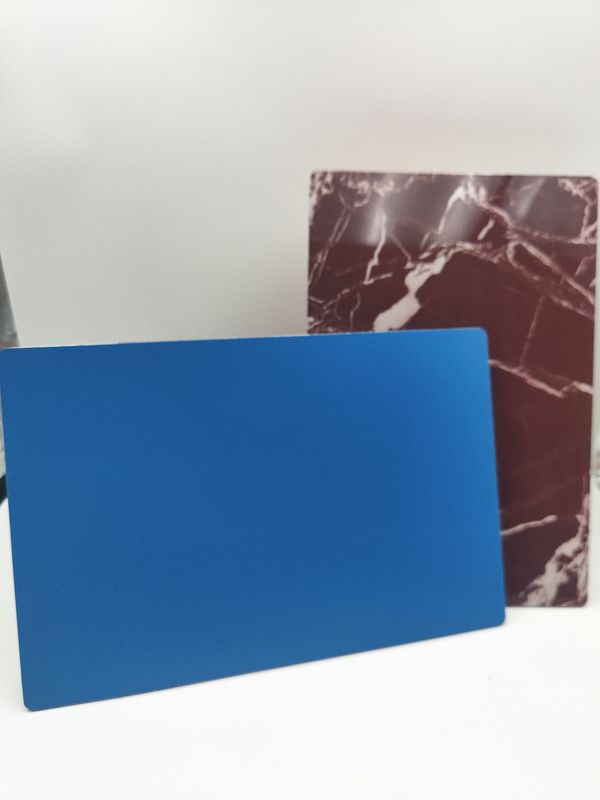

| Aluminum Layer Thickness: | 0.1mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm | Color: | Regular Color,Solid Color,High Gloss,Wood Grain,Stone Grain,Mirror Finish,Brushed,Special Effects |

| Material: | ACP Plastic Sheet | ||

| Highlight: | Brushed Aluminum Plastic Composite Panel,Aluminum Plastic Composite Panel 2440mm,4mm Acm Panel 2440mm |

||

Product Description

ACP Plastic Sheet - 0.5mm Aluminum Layer, Brushed Surface for Billboards, 4.0mm

Product Description:

Constructed from two distinctively different materials - metal and non-metal, the aluminum plastic board is a harmonious blend that both encapsulates the fundamental properties of metal aluminum and non-metal polyethylene plastic and transcends their limitations.

It exhibits a plethora of superior attributes, such as opulence, dazzling color variations, weather endurance, resistance against corrosion and collision, fire and moisture protection, noise and heat isolation, and earthquake resistance. Moreover, It features its lightweight, ease of molding, and simple mobility and installment, which add to its advantages.

Features:

Aluminum-plastic panels are a highly popular material in the construction and decoration industry. This is due to the combination of its light weight with strength and durability, making them easy to install and transport while still maintaining their performance.

Furthermore, it has excellent weather resistance and does not show signs of wear and tear like other materials when exposed to harsh conditions. It also comes in a variety of colors and designs that are easy to customize to meet different aesthetic needs.

This material is also very easy to maintain and clean, without the need for any special maintenance. It is non-toxic and safe for the environment as it can be recycled. In addition, its good sound insulation performance makes it ideal for workplaces, hospitals, and schools.

Finally, aluminum-plastic panels have good fire resistance that can prevent the spread of flames and safeguard the structural integrity of buildings in the event of a fire.

Technical Parameters:

Applications:

Structural Outdoors provides exterior solutions for tall buildings, standalone residences, organizational headquarters, and commercial edifices.

Space Decor specializes in augmenting living, working, and business spaces with wall applications, overhead themes, and room dividers.

Public Notices specializes in constructing outdoor ads, retail banners, navigational posts, graphic ads, and platform exhibits.

The Movement Sector offers structural components for public buses, locomotives, subway rides, and flying machines.

Decorative Joinery is an expert in fashioning trendy furniture, clothing storage, culinary units, and other interior attachments.

Industrial Surroundings is experienced in producing practical items for engineering settings, safeguarding apparatus, and sanitized surroundings.

Consumer Spaces focuses on planning commercial spaces, transaction booths, and showcasing units.

Guest Services is proficient in creating infrastructural designs in resting places, vacation spots, and culinary establishments.

For wellness buildings, Structural Outdoors produces facade applications due to its antiseptic and enduring nature.

Structural Outdoors is also adept in producing items for pedagogical sites, such as campus settings, academic centers, employing it for communication tools, seating, and space segmentation.

Likewise, Structural Outdoors is an expert in providing infrastructural needs in activity zones, such as match venues, wellness areas, and recreational centers.

Structural Outdoors also provides external and informational applications in connectivity centers, such as air junctions, rail hubs, mass transit locales, and shipping points.

Product processing performance:

Our manufactured aluminum composite panels are readily tailored using both woodworking and metalworking instruments. Operations such as chopping, sectioning, milling, perforating, compressing, folding, and arching are possible. This ensures architectural decorative requirements are met with precision, especially designs like curves, opposing curves, minimal bend edges, and both inner and outer angles. Such adaptability is not often seen in other ornamental resources.

1.Segmenting: Tools span from hand-operated to electric and ring saws.

2.Ridge Milling: Post-processing with a mobile milling machine, one can shape it into diverse polyhedral figures.

3.Corner Deduction: After operations with a perforating device and corner reduction equipment, integration is achievable.

4.Binding: Combine using hot wind devices and plastic welding sticks.

5.Angle Molding: Following ridge milling, the desired angles can be formed.

6.Arching: Utilize 3-pivot or 3-barrel machines for this purpose.

7.Marking: Utilize screen print boards for markings.

8.Consolidating: Use mechanisms like rivets, spikes, and automated screws.

9.Puncturing: Perforations are feasible with a general puncher.