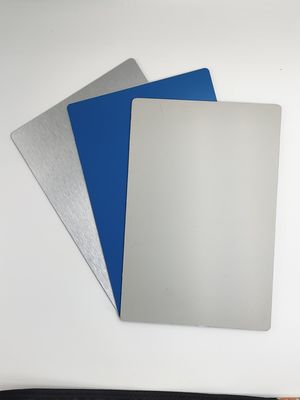

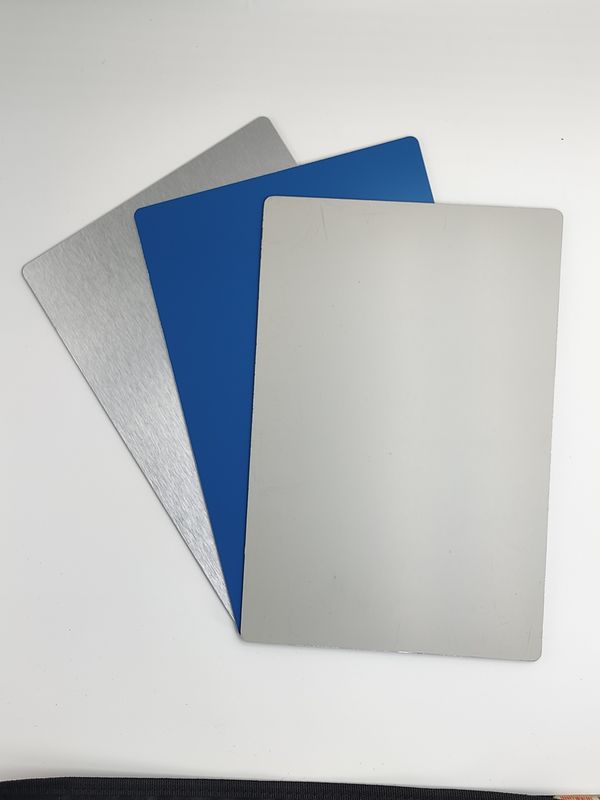

Anodized ACP Plastic Composite Sheeting , Mirror Finish 5mm Aluminum Sheet

Product Details:

| Place of Origin: | China |

| Brand Name: | richly bound |

| Certification: | ISO 9001:2008;GB 8624-2012;GB/T 17748-2016 |

| Model Number: | High-strength aluminum composite panel |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 sqm |

|---|---|

| Price: | depends on your needs |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Delivery Time: | usually within 14 working days |

| Payment Terms: | T/T |

|

Detail Information |

|||

| Material: | ACP Plastic Sheet | Surface Coating: | Polyester (PE),High-performance Polyester (DHPE),Fluorocarbon (PVDF),PVC Film,Anodized |

|---|---|---|---|

| Aluminum Layer Thickness: | 0.1mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm | Application: | Exterior Wall, Balcony, Ceilings, Partitions, Doors, Column Casings, Equipment Panels, Interior Decoration, Interior Design, Furniture Surfaces, Curtain Walls, Billboards, Exhibitions, Signs, Signboard Doors, Coffee Shop Interior Design, Renovation Of Old |

| Color: | Regular Color,Solid Color,High Gloss,Wood Grain,Stone Grain,Mirror Finish,Brushed,Special Effects | Size: | 1220*2440mm |

| Sheet Thickness: | 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm | ||

| Highlight: | Anodized Plastic Composite Sheeting,Mirror Finish Plastic Composite Sheeting,Mirror Finish 5mm Aluminum Sheet |

||

Product Description

Anodized ACP Plastic Sheet with Mirror Finish, for Signs, Aluminum Composite Panel

Product Description:

An Aluminum Plastic Panel: A Versatile and Sustainable ChoiceAn Aluminum Plastic Panel (ACP) is a flat panel that is composed of a non-aluminum core sandwiched between two aluminum sheets. This practical and modern choice is often coated with Polyvinylidene Fluoride (PVDF) or Polyethylene (PE), which allows the panel to come in a vast array of colors and finishes. Not only is this an ideal choice for architectural purposes, but ACP also provides great features for commercial and interior designs. This material is recognized for its outstanding durability, light weight, and flexibility, in addition to being an energy-efficient and recyclable material. This type of panel is now becoming more and more relevant in the current trend of sustainable and eco-friendly architectural materials. Apart from architecture, ACP is also widely used for shop facades, advertising signs, and other interior designs.

Features:

Featherweight: Aluminum composite panels have an elevated strength-to-weight ratio. In comparison to aluminum sheets and steel, they have an areal weight nearly 60% and 30% lower respectively.

Exceptional Cohesion: These panels demonstrate an utilize a high 180° peel strength, and have no separation after prolonged service.

Weather Endurance: After exposure to outdoor weather, the aluminum sheet and plastic core material experience negligible alteration in color or gloss, no shedding of the coating, and an average life expectancy exceeding twenty years.

Resistance to Corrosion: With a resilient PVDF fluorocarbon resin coating, the surface layer exhibits high adhesion strength and can oppose the effects of acid, base, and salt spray.

Withstands Wind Load: Performance level satisfies the requirements of A grade wind load resistance for tall buildings.

Flame-Proof: Comprised of non-toxic polyethylene and non-flammable aluminum plates, this material possesses a high degree of fire resistance.

Technical Parameters:

Applications:

External Architecture: Utilized for external coverings on skyscrapers, standalone residences, business offices, and commercial buildings.

Inner Decoration: Used for interior ornamentation in households, office spaces, and commercial areas, involving wall accents, ceiling schemes, and room dividers.

Promotional Displays: Implemented for billboards, store signage, direction indicators, digital advertisements, and display stages.

Transit Infrastructure: Used in the formation of parts for buses, trains, metro systems, airplanes, and nautical vehicles.

Interior Design: Utilized for crafting furniture styles, wardrobes, kitchen cabinet faces, and other indoor installations.

Industrial Implementations: Utilized in production facilities as protective covers for machinery, safety casings for equipment, and sterile room uses.

Consumer Facing Designs: Incorporated in the design of retail stores, kiosk layouts, and indoor display segments.

Our Company:

FAQ:

- Q1: What is ACP Plastic Sheet?

- A1: ACP Plastic Sheet is a High-strength aluminum composite panel, produced by the Chinese brand Richly Bound and certified by ISO 9001:2008;GB 8624-2012;GB/T 17748-2016.

- Q2: What are the features of ACP Plastic Sheet?

- A2: ACP Plastic Sheet features high strength, light weight, strong weather resistance, easy maintenance, and fireproof properties.

- Q3: What is the size of ACP Plastic Sheet?

- A3: The size of ACP Plastic Sheet is usually 1,220 mm x 2,440 mm or 1,220 mm x 3,050 mm.

- Q4: What is the surface finish of ACP Plastic Sheet?

- A4: ACP Plastic Sheet has a glossy or matte finish.

- Q5: What is the application of ACP Plastic Sheet?

- A5: ACP Plastic Sheet is widely used in interior and exterior decoration, such as wall cladding, ceiling, partition wall, advertising signs, and so on.